In residential and industrial environments, gas pipeline systems are a crucial component in ensuring a secure energy supply. Whether using natural gas, liquefied petroleum gas, or other types of gas, the quality of pipeline connections directly affects the safety, stability, and durability of the gas system. Corrugated stainless steel tubes, as a new type of pipeline connection material, have become an ideal choice for connecting gas equipment due to their numerous advantages.

1. Structural Characteristics of Corrugated Stainless Steel Tubes

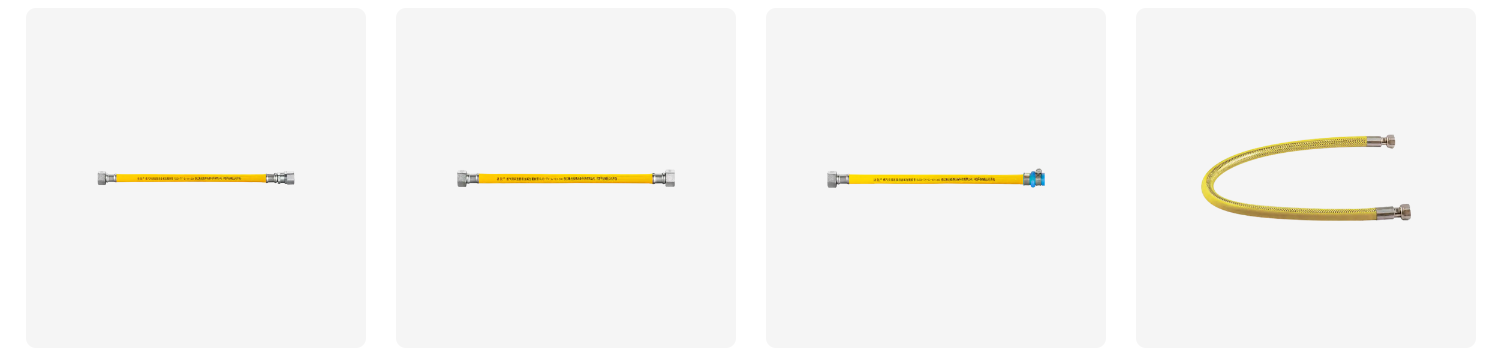

Corrugated stainless steel tubes are made of stainless steel with a corrugated surface. This corrugated design gives the tubes high flexibility and bendability. Compared to traditional rigid metal pipes (such as copper and steel pipes), corrugated stainless steel tubes can withstand greater tension and bending, adapting to different installation environments and complex spatial structures without breaking.

The smooth inner wall of corrugated stainless steel tubes reduces friction in gas flow, helping to maintain smooth gas flow. Furthermore, the corrugated structure makes the tubes more shock-resistant, effectively coping with pressure changes caused by external vibrations or equipment operation, reducing the risk of pipeline damage.

2. Advantages of Corrugated Stainless Steel Pipes

(1) Enhanced Safety

Safety is paramount in gas pipeline systems, and corrugated stainless steel pipes offer a natural advantage in this regard. Firstly, due to their high tensile strength and corrosion resistance, they effectively resist the corrosion of gas and the erosion of chemicals in the external environment, preventing the risks of pipe aging, cracking, and leakage. Secondly, the flexibility of corrugated stainless steel pipes allows for closer fitting to different connection requirements during installation, reducing potential leaks caused by improper pipe connections.

Furthermore, corrugated stainless steel pipes possess excellent seismic performance, making them particularly suitable for earthquake-prone areas. In the event of sudden events such as earthquakes, corrugated stainless steel pipes effectively absorb vibration energy, reducing damage to the gas pipeline system and ensuring its stability.

(2) Convenient Installation and Cost Savings

Traditional rigid metal pipes require numerous tools and welding processes for installation, while corrugated stainless steel pipes, due to their excellent flexibility and bendability, can be easily bent and cut as needed, greatly simplifying the installation process. They can be flexibly installed in complex spaces, especially suitable for confined spaces or locations requiring multiple bends. Furthermore, corrugated stainless steel pipes typically utilize crimping or quick-connect couplings at joints, eliminating the need for welding and excessive procedures, further reducing construction costs and time. Due to the durability of stainless steel, the maintenance costs of corrugated stainless steel pipes are also lower.

(3) High Temperature and Corrosion Resistance

Gas pipelines are exposed to various environments over extended periods, especially in high-temperature, high-humidity, or chemically polluted environments, making corrosion resistance and high-temperature resistance crucial. Corrugated stainless steel pipes, made from high-quality stainless steel, possess extremely strong corrosion resistance, resisting the erosion of water, oil, acids, alkalis, and other chemicals, adapting to harsh environments. Even at high temperatures, corrugated stainless steel pipes maintain their stability and strength, ensuring long-term use without damage.

(4) Improved Durability and Service Life

The durability of corrugated stainless steel pipes is outstanding. Due to the rust-free nature of its material, corrugated stainless steel pipes do not rust or corrode like ordinary steel pipes, achieving a service life of over 20 years. Even under extremely harsh environmental conditions, corrugated stainless steel pipes can operate stably for extended periods, reducing the inconvenience and cost of frequent pipe replacements

3. Application Scenarios of Corrugated Stainless Steel Tubes

Corrugated stainless steel tubes are widely used in residential, commercial, and industrial applications, and are particularly suitable for connecting gas appliances.

Here are some typical application scenarios:

Household Gas Connections: In the installation of household gas appliances (such as gas stoves and water heaters), corrugated stainless steel tubes provide a flexible and safe pipe connection solution. Their ease of installation and maintenance makes them an ideal choice for household gas piping systems.

Commercial Kitchens and Catering Industry: The frequent use of gas appliances in commercial kitchens requires piping systems with high safety and durability. The high-temperature resistance and corrosion resistance of corrugated stainless steel tubes are ideal for this high-intensity, frequent-use environment.

Industrial Gas Systems: In some industrial production processes, gas pipelines need to withstand harsh conditions such as high temperatures and chemical corrosion. Corrugated stainless steel tubes, with their excellent corrosion resistance and high-temperature stability, have become an indispensable piping material in industrial gas systems.

Choosing corrugated stainless steel tubes to connect gas appliances provides greater safety, convenience, and durability. Its superior corrosion resistance, high-temperature resistance, and seismic performance ensure the long-term stable operation of gas pipeline systems, reducing the risk of malfunctions and leaks. Combined with its flexible installation methods and low maintenance costs, corrugated stainless steel pipes have become the preferred material for modern gas equipment connections.

English

English 中文简体

中文简体 Español

Español عربى

عربى