Content

1. Why Replace Gas Pipelines?

Gas pipelines are subjected to complex conditions such as long-term pressure, corrosion, and external environmental interference, and their materials and performance will gradually age and deteriorate over time.

The main purposes of replacing old pipelines include:

Preventing Leakage Accidents: Pipeline corrosion, cracks, and seal failure are the main causes of gas leaks, which in turn are the source of serious accidents such as fires and explosions.

Increasing Operating Pressure: With urban development and increased gas demand, some older pipelines, due to insufficient pressure bearing capacity or small diameters, cannot meet modern transmission and distribution requirements and require replacement and expansion.

Eliminating Outdated Materials: Early materials such as cast iron pipes and galvanized steel pipes have poor corrosion and seismic resistance and have been replaced by safer new materials.

Eliminating External Hazards: Due to urban changes, some pipelines may be occupied by buildings or located in areas prone to geological disasters, requiring relocation or replacement.

2. Replacement Standards for Different Pipelines

Gas pipeline replacement is not simply based on age; it is a comprehensive assessment based on material, operating conditions, risk assessment, and safety regulations. They can be mainly divided into the following categories: (1) Municipal and courtyard pipe networks (outdoor public pipes) The replacement of these pipes is usually the responsibility of the gas company and is carried out in accordance with national policies (such as the "Work Plan for the Renovation and Reconstruction of Aging Urban Gas Pipelines (2022-2025)") and industry specifications. Material elimination type replacement: All gray cast iron pipes: This material is brittle, has poor seismic resistance, and is prone to leakage at the interface, making it the primary target for renewal. Ductile iron pipes that do not meet safety operation requirements: Although their performance is better than gray cast iron, some pipes that have been in operation for many years have aging problems and need to be replaced if they are assessed to not meet safety requirements. Replacement for over-age use: Steel pipes and polyethylene (PE) pipes that have been in operation for 20 years and have been assessed to have safety hazards: Although PE pipes are corrosion-resistant, their mechanical properties will decline after exceeding their designed service life. A comprehensive safety assessment is required to determine whether to replace them based on the assessment results. Pipelines with less than 20 years of operation but presenting safety hazards that cannot be guaranteed through control measures: If the hazard is caused by third-party construction damage, severe corrosion, foundation settlement, or other factors, they must be replaced immediately.

Relocation-based replacement for hazardous conditions:

Pipelines encroaching on buildings, with insufficient safety clearances, or located in geological disaster areas: These pipelines cannot be effectively inspected and maintained, presenting an extremely high risk and requiring relocation or replacement.

3. User Facilities (Indoor Pipelines)

Indoor pipelines are directly related to user safety, and their replacement standards are more specific and closely related to the user.

Replacing Connecting Hoses:

Rubber hoses must be eliminated: The national mandatory standard "Gas Engineering Project Specification" (GB55009-2021) explicitly prohibits the use of old-style rubber hoses. Due to their short service life (only 18 months), susceptibility to aging, cracking, and rat bites, they are the primary cause of indoor gas accidents.

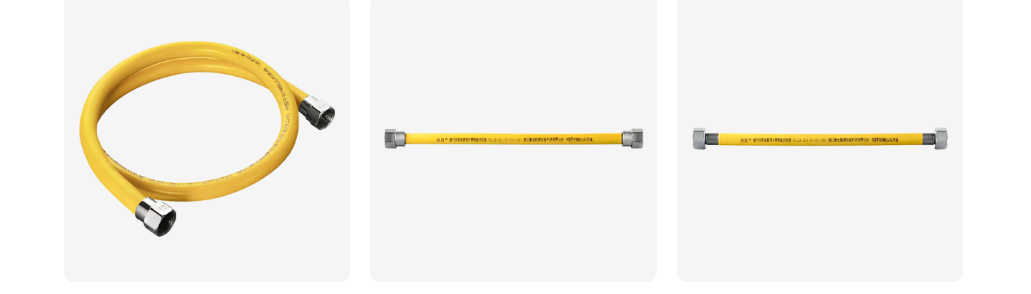

Metal bellows are recommended: They offer a service life of 8-10 years, are corrosion-resistant, crush-resistant, and rat-resistant, making them the preferred choice for indoor gas pipeline safety. Even so, they must be replaced promptly after expiration.

Indoor risers and branch pipes:

Once discovered by professional safety inspectors, old galvanized steel pipes that are severely corroded, have reduced sealing properties, or have been illegally modified, the user must be advised to replace them immediately, typically with safer thin-walled stainless steel pipes.

Installation and Replacement of Safety Devices:

As mentioned above, according to the GB55009-2021 standard, household pipes must be equipped with a gas shut-off valve that automatically shuts off the pipe when abnormal pressure occurs (such as a hose detachment causing low pressure, or a pressure regulator failure causing high pressure). This does not require direct pipe replacement, but it is a mandatory safety feature of the piping system.

4. How to Determine Whether a Gas Pipeline Needs Replacement?

As an ordinary user, you can make a preliminary assessment and coordinate with the following methods:

Check the material: Inspect the hoses connecting the stove and water heater. If they are made of rubber, contact the gas company immediately to replace them with metal bellows. Check the age: Even if using metal pipes, pay attention to their service life (generally 8-10 years) and replace them when they are due.

Check the appearance: Regularly inspect pipe joints, valves, and other areas for rust, oil stains, and cracks, or use soapy water to check for bubbles (if any, this indicates a leak).

Smell: Pay attention to any odor in your home, similar to rotten eggs, which may indicate a gas leak.

Cooperate with professional inspections: Gas companies provide regular, free home safety inspections (usually every two years). Be sure to cooperate actively and take all notices from inspectors regarding potential hazards and address them promptly.

5. What to do if a potential hazard is discovered or replacement is necessary?

Immediate Action: If you suspect or discover a gas leak, strictly adhere to the following principles: "1. Ventilate (open doors and windows); 2. Close valves (turn off the main valve); 3. No fire (strictly prohibit the use of electrical appliances and open flames); 4. Evacuate (evacuate personnel); 5. Report a problem (get to a safe area outside and call the gas company).

Professional Operations: Never replace gas pipes yourself! Pipeline installation and modification must be performed by qualified professionals from a qualified gas installation and maintenance company.

Qualified Products: Replacement hoses, valves, and other accessories must be purchased from qualified products that meet national standards. Avoid using cheap, uncertified parts.

English

English 中文简体

中文简体 Español

Español عربى

عربى